The inman power component

Is low profile and extremely comfortable compared to other components available

The IPC may be used for many types of movement, from simple space regainers to advanced 3-ways arch development appliances.

The IPC may be used for many types of movement, from simple space regainers to advanced 3-ways arch development appliances.

How It Works

The power of the inman power component

Using compressed coil spring to generate orthodontic force is nothing new, the way the Inman Component archives this is revolutionary. I always thought that the sliding locks relying on set screws to compress open coil must be a clinical nightmare. The problem was besides crimpable stops, how could we eliminate these set screw devices? One day while using a zip tie I thought to myself; if I could turn a zip tie into Stainless Steel it would be a very useful orthodontic component.

How does it work?

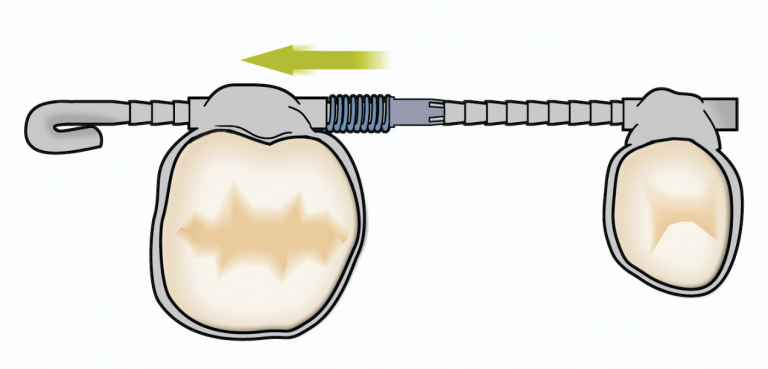

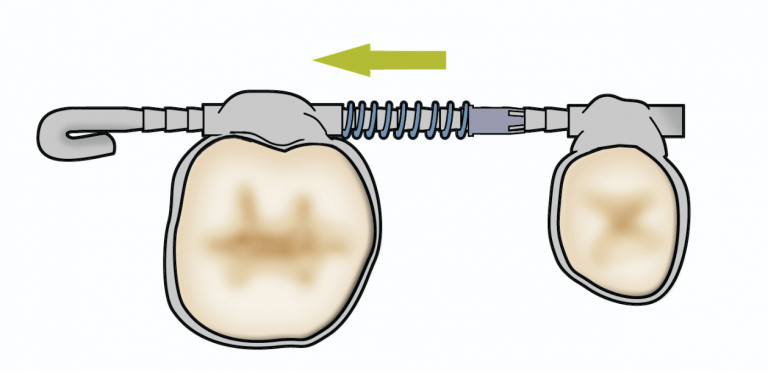

The IPC shaft is fabricated with conical offsets kind of like if you stacked cones upside down and welded them all together. The lock is designed with 4 small tabs or living hinges that are capable of flexing. as the lock slides forward the tabs flex over the thickest part of the cone and then collapse into the valley where the next

cone begins. this causes an audible click that also translates to feel as the clinician advances the lock, each of these clicks equals to one millimeter of advancement. So if the IPC is placed in an appliance where between the lock and a fixed tube open coil spring is trapped, advancing the lock will compress the coil and generate and orthodontic force. Please not that the lock cannot be reversed

How is it used?

It can and is used on many types of orthodontic appliances including arch developers, space regainers, molar distalizers and more. I have seen some very clever appliance designs using the IPC to close space and to extrude teeth. Use your imagination as the IPC is not limited but remember to never bend it in the tooled section without heat treating it almost to the point of annealing.

How do I use it?

We suggest that before any appliance is fabricate that the IPC is tested one or two times. Simply slide the lock toward the barrel like detail until the lock is free from the shaft, reinsert the lock on the other end and slide to the first click. some labs like to sticky wax to cover the lock to make sure it does not move during fabrication, do this only after all soldering is done.

INMAN Power Component 3953 NW 126th Ave.